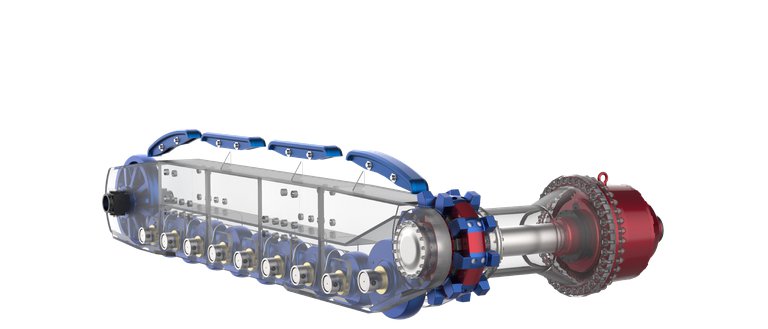

Boundary has engineered and improved many components on the CAT 7495 lower works.

Lowering Cost of Ownership

This desire to improve products and in-service effectiveness has resulted in Boundary’s product development standards that have grown our reputation and site acceptance over the last 40 years

A measure of the stature and skill of our design department is represented on the multitude of improvements on hydraulic shovels, rope shovels and hard rock drills.

The above design improvements represent a very small portion of the advancements we have made on open-pit mining equipment. Boundary’s core design work also includes the capability and expertise to design copper ladles and slag pots, apron feeder pans and rotary breaker components.

Improved

Boundary has engineered and improved many components on the CAT 7495 lower works.

Re-design of slider system to eliminate weld on slider caps.

Design of replaceable lug drive tumbler to increase hardness of tumbler teeth.

Improved material design and heat treatment processes on rear idlers, lower rollers and front idlers.

Ability to supply track shoes in both alloy and manganese without modifying the side frames.

Extended Wear

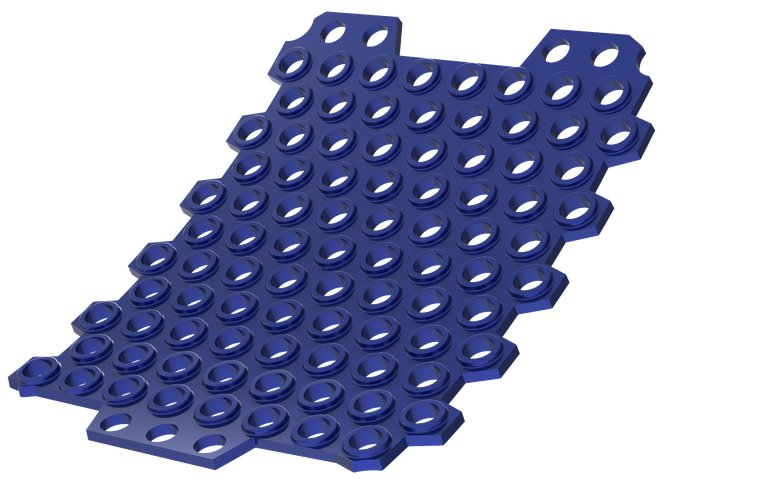

Since inception Boundary has been re-designing rotary breaker plates, plows and lifters.

Elimination of fabricated designs.

Castings are specified with proven materials to extend wear life.

Re-design of breaker plates to improve sizing and breaker productivity.

Re-design of lifters and plows to extend life and usability.

Optimize Productivity

With a proven history designing and manufacturing ladles and slag pots over 100T Boundary is relied upon by Copper Smelters worldwide.

Complete ladle or slag pot design to optimize productivity.

Unique proprietary design features to reduce ownership cost and serviceability.

Loaded and thermal finite element analysis to prove designs and reliability.