United Gear’s propel rebuilds have been tested in oilsands, coal and hard rock conditions and have met the demands head on by:

Since 1965, we have developed a reputation for delivering quality and proven gear systems for processes in mining, shipping terminals, wind, cement, aggregate, pulp and paper and forestry.

On the mining side, we have vast experience supporting transmission rebuilds on rope shovels, hydraulic shovels, hard rock drills, apron feeder drives, and conveyor drives at Canada’s key mining operations. Using our extensive expertise, we’ve made countless efficiency improvements on swing, propel and hoist transmissions for mining equipment like the CAT 7495 and P&H rope shovels.

We Rebuild & Optimize Gearboxes.

United Gear follows strict AGMA standards in all aspects of our manufacturing process. We operate a Quality Management System (QMS) which complies with the requirements of ISO 9001:2015 with the registration covering the QMS for Manufacturing of American and Metric Standard Gears and associated products.

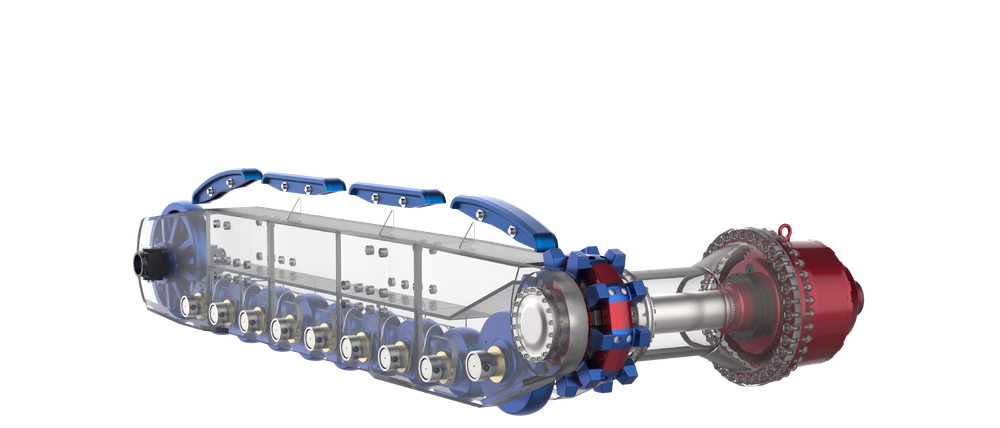

The combination of United Gear’s drive train and Boundary’s lower works gives the CAT 7495 a strong performance boost.

United Gear’s propel rebuilds have been tested in oilsands, coal and hard rock conditions and have met the demands head on by:

Improved ring gear, housing bore repair process and upgraded geometry.

Addressing numerous weaknesses in material and carrier properties.

Advanced manufacturing of propel components to ensure timely turnaround.