To reduce cost and increase the sprocket hardness, Boundary has developed a unique proprietary process to re-ring Hitachi drive tumblers.

Tested Components

In the last 40 years Boundary’s hydraulic shovel undercarriage components have been tested in the most challenging mining regions in the world and demonstrated the highest level of performance.

To reduce cost and increase the sprocket hardness, Boundary has developed a unique proprietary process to re-ring Hitachi drive tumblers.

One piece drive tumblers have a limited hardness to cut the spline. This rebuild process allows Boundary to increase the hardness on the new ring and extend life.

Available on Hitachi EX2500 through EX5500 models.

100% interchangeable with OEM.

Boundary’s Hitachi track shoes have been optimized for reliability.

Cast in a proprietary alloy to achieve hardness levels exceeding industry standards.

The material has been designed to have an impact value suitable for mining operations in Canada, United States, Chile, Peru, Africa and anywhere else in the world.

100% interchangeable with OEM.

Optimized material and heat treatment processes to extend life.

Forged and hardened to 40 HRc.

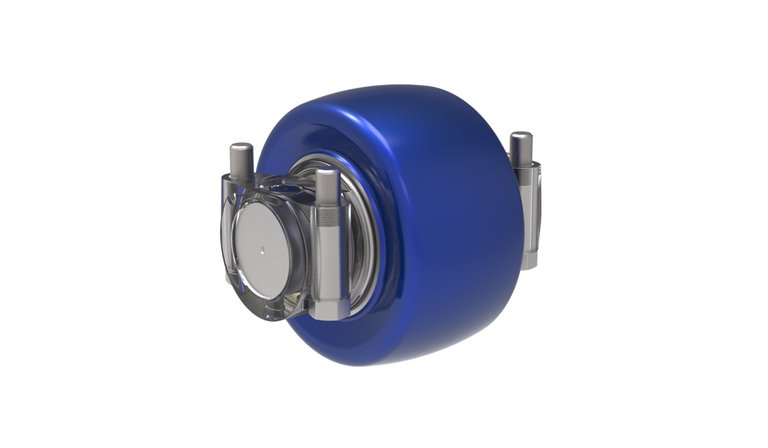

Proven modified manganese bronze bushings.

100% interchangeable with OEM.

Manufactured in a proprietary alloy to ensure reliability, wear life and lower cost of ownership.

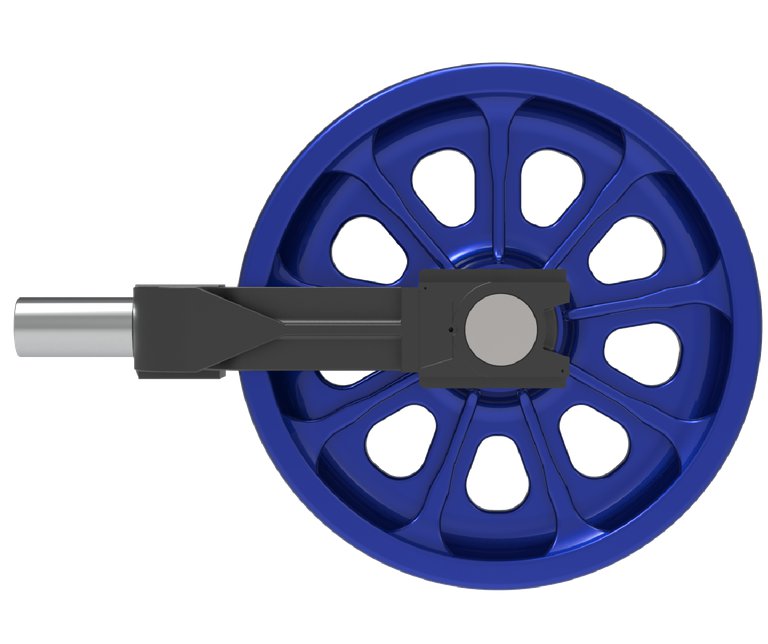

In addition to having a proprietary alloy, the idler wheel is induction hardened.

Supplied with Toughmet bushings.

100% interchangeable with OEM.

Find

Boundary offers first-class replacement parts for Hitachi mining shovels. We manufacture aftermarket parts that can replace Hitachi parts. Boundary Equipment has a long history as an aftermarket parts supplier for Hitachi equipment that speaks for itself. Exceptional quality, shortest lead time, affordable pricing and industry-wide accepted warranty supported with scheduled on-site inspections are what our Genuine Boundary Products offer to customers.